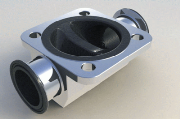

Bürkert has extended its BBS range of stainless steel products for hygienic processing applications in food, pharmaceuticals and biotechnology, with the introduction of a new range of PFA-lined stainless steel diaphragm valves for use with aggressive chemicals.

Bürkert has extended its BBS range of stainless steel products for hygienic processing applications in food, pharmaceuticals and biotechnology, with the introduction of a new range of PFA-lined stainless steel diaphragm valves for use with aggressive chemicals.

The PFA liner integrated into the new diaphragm valves is a fluoropolymer (highly resistant to solvents and acids) said to be resistant to most aggressive chemicals and acids, and with a low level of porosity. It is also tolerant of higher temperatures, with the capability for operation up to 260°C.

The new diaphragm valves complement Burkert’s existing BBS range of sterile ancillary piping, flanges, connectors, indicators, sampling systems and vessel equipment.

They can be used with Burkert’s valve, sensor, process control, hazardous area and specialist products, enabling the company to provide customised hygienic processing solutions.

In demanding sectors, where compactness, smart communications, plant footprints, cleaning and sterilisation, dead legs, cross-contamination, and validation are concerns, Bürkert and BBS products deliver higher process efficiency and higher yields, by offering unlimited process modularity.