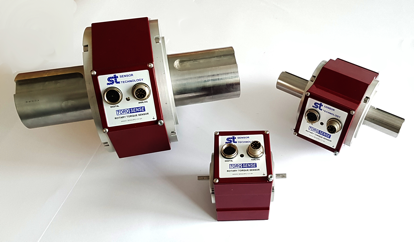

Sensor Technology has extended its new range of non-contact torque sensors up to 13,000Nm. When the range was launched in late 2020, the largest unit was 500Nm.

“We have been very encouraged by the interesting in the new sensors,” says Sales Manager, Mark Ingham. “The launch plan was originally to start with the commodity sizes and gradually introduce the larger sensors, but interest has been such that we need to meet demand almost immediately.”

Sensor Technology has specialised in wireless torque sensing for many years, mainly offering a solution based on detecting surface acoustic waves. It’s new sensors, designated the SGR510/520 series, however use a full four element strain gauge bridge design.

“The new sensors have the advantage that they can accurately measure and record sudden spikes in torque load,” explains Mark. “In the past this data was generally not required by plant and machinery operators, but with the growth in automated continuous monitoring it is becoming more and more important. Any torque spike could have an immediate effect on operations, while a series of them may indicate the beginnings of a problem.”

The new design also compensates for any extraneous forces, such as bending moments, inadvertently applied to the sensor, improves sensitivity and has a wide temperature tolerance. Again, these are all attributes that have become increasingly desirable in recent years as there is an increasing need for sophisticated modelling of operational performance.

In use, the four strain gauges are glued onto the low hysteresis high performance nickel chromium steel shaft that is to be monitored in a square formation set at 45deg to the axis of rotation. When torque is applied to the shaft two gauges are stretched into tension and two go into compression, the difference between the tension and compression values being proportional to the torque in the shaft.

An ultra-miniature microcontroller, mounted on a rotor and powered by an inductive coil, measures the differential values in each strain gauge and transmits them back to the stator digitally, via the same coil. State of the art strain gauge signal conditioning techniques are then used to convert raw live data into precise torque value measurements. This set up provides a high bandwidth, high over range and overload tolerances.

The TorqSense SGR510/520 offers several significant advantages over conventional torque sensors. It eliminates the sort of noise pickup and signal corruption associated with slip ring and other analogue methods of transferring torque data from rotor to stator. The over range capacity means true overrange values are captured rather than ‘maxing-out’ at the technology’s upper limit, while the 400% mechanical overload limit is unlikely to be breached in the vast majority of applications.

Mark explains further: “External noise pickup into the wiring is virtually eliminated due to the short distance between the strain gauges and the rotor’s measuring circuits. Further, multipoint calibration reduces any linearity errors within the sensor. Measurement of shaft temperature allows for full temperature correction for changes in modulus of the shaft over the full temperature range of -20 to +50 deg C”

“For ease of use there is a built-in test function,” says Mark, who summarises the new TorqSense SGR510/520 with: “Most torque sensors require the use of slip rings to transfer torque readings from the rotating shaft to the static readout. These are noisy in use, slow and fiddly to set up and, as wearing parts, are not always reliable.

The range extension means the SGR series is available in sizes from 1Nm to 13000Nm. All units are accurate to +/-0.1% and resolution to +/-0.01% of the transducer’s full scale

Other features include an optional adjustable moving average filter, power supply range from 12VDC to 32VDC, user configurable analogue output voltages, a choice of RS232 communications, USB interface, CAN bus interface, external Ethernet gateway, TorqView software and LabView virtual instruments.

The new SGR510/520 series will be suitable for many applications for testing motors or driven loads in many industries including Defence, aerospace, and Automotive. Quality Assurance depts in gearbox, pump, motor, and bottle capping machinery manufacturers will find the ease of use appealing, and Technical Departments of Universities and Research Institutes will find the versatility of the available customer selectable options will help with precise measurements.

Another area of increasing applications is in mixing and extruding where viscosity and consistency measurement during processes is becoming increasing important.