Sick (UK) has extended the capabilities of its optical linear measurement sensor portfolio with the new OLM200, for high performance materials handling applications.

Sick (UK) has extended the capabilities of its optical linear measurement sensor portfolio with the new OLM200, for high performance materials handling applications.

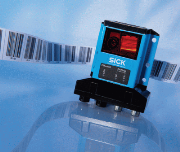

The enhanced positioning sensor, which delivers increased accuracy, speed and repeatability, uses a barcode tape to provide non-contact linear positioning on both curved and straight tracks. The sensor continually reads up to three barcodes to build an absolute positional value, ensuring optimal performance even if a barcode is missing or damaged.

The sensor, which is supported by additional plant control system connectivity, has high operating speeds which can be utilised to achieve increased volume throughput, making it suitable for use with applications such as rail-mounted shuttles, overhead conveyors, rotary tables, turntables, slewing rings hoisting systems and robots, commonly used in the automotive, textile and film industries.

A Profibus DP interface enables connection to more complex distributed control systems. As well as diagnostic information, both position and speed can be communicated, enabling enhanced system control.