Connectors intended for industrial machinery or control cabinets have to ensure durable and reliable electrical connections, while also offering easy handling and the ability to customise them to meet the requirements of different industries and applications. This article discusses two new developments in industrial connectivity that address these challenges

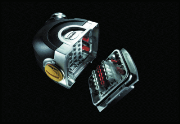

Han-Yellock® (Fig1) is a new generation of industrial connectors which combines flexibility, reliability and ease of handling in a functionally designed package with elegant appearance. The basic concepts behind Han-Yellock® are simple and effective: its basic design allows it to be assembled and, if necessary, dismantled from both sides – either from the machine or cabling side.

The connections are moved from the control cabinet to the connector, which effectively expands its application potential. The connector thereby eases the load on the control cabinet, facilitates installation and prevents errors that can be caused during installation in the control cabinet. In the short term, this enables the further reduction of the size of the control cabinet and the amount of mechanical engineering required.

The connections are moved from the control cabinet to the connector, which effectively expands its application potential. The connector thereby eases the load on the control cabinet, facilitates installation and prevents errors that can be caused during installation in the control cabinet. In the short term, this enables the further reduction of the size of the control cabinet and the amount of mechanical engineering required.

Five-pin modules can be snapped into the casing system without tools. Depending on requirements, the five contacts, each with a current carrying capacity of 20A, can be switched to 2, 3, 4 or 5-way links. Switching is via coloured socket adaptors that are snapped on by users on the mating side.

This terminal block function is now incorporated in the connectors; integration is quick and service-friendly, while space requirements are minimal. This connectivity approach is attractive for market areas that require increasingly smaller and ever more compact machinery and equipment. These solutions open up a number of options and possibilities for electrical planning and procurement, such as the simplification of circuit diagrams and reductions in wiring errors and lower material and wiring costs.