Medical devices must perform precisely to specification or they may seriously limit the ability of a healthcare professional to effectively and safely treat their patient. Force & torque testing is an essential requirement in modern development and manufacture of medical devices, quantifying the mechanical aspects of medical devices in order to guarantee the usability and fitness-for-purpose of the device, to ensure compliance with the many stringent industry standards and to continually achieve 100% quality in production.

Medical devices must perform precisely to specification or they may seriously limit the ability of a healthcare professional to effectively and safely treat their patient. Force & torque testing is an essential requirement in modern development and manufacture of medical devices, quantifying the mechanical aspects of medical devices in order to guarantee the usability and fitness-for-purpose of the device, to ensure compliance with the many stringent industry standards and to continually achieve 100% quality in production.

Mecmesin test solutions for manufacturers of medical devices and medical packaging include:

- 90°, 135° & 180° peel testing of adhesive dressings, tapes & packaging materials

- Actuation force of metered dose inhalers & pen injectors

- Coefficient of friction of packaging materials

- Crush/pierce testing of tablets and capsules

- Fatigue testing & failure analysis of orthopaedic implants

- Flexural testing of needles

- Insertion & extraction force testing of hypodermic needles

- Joint strength testing of connectors

- Needle hub retention strength

- Penetration force of spring-loaded lancets in blood glucose monitoring systems

- Pierce testing of films & foils

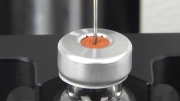

- Precision torque on Luer lock connectors & drug delivery devices e.g. pen injectors

- Release torque on child-resistant closures (CRCs)

- Scapel blade and needle sharpness testing

- Syringe plunger actuation & ‘travel’ force assessment

- Tensile strength & elongation of medical tubing, gloves & medical textiles

- Torque testing of rotary controls on medical systems

- Trackability testing of stent delivery systems

plus many more …

plus many more …

Since 1977 Mecmesin has been providing customers in the medical industry, including Cardinal Health, Owen Mumford, Bespak, BD and the University of Brighton Medical School with accurate, affordable and bespoke force & torque testing solutions.

Bespak, a leader in specialty medical devices for inhaled drug delivery and anaesthesia, is using a Mecmesin MultiTest 1-i force test system to test the springs used within the operating mechanism of these devices. “We have used Mecmesin equipment for a number of years to perform compression and tension tests on helical springs intended for use in our respiratory drug delivery devices. We now estimate that every second, more than a thousand people rely on a Bespak device to help them breathe and as our testing requirements have grown, so too has our relationship with Mecmesin. Today, we use their computer-controlled test systems to guarantee the quality of our supplied materials,” Peter Haken, Quality Engineer, Bespak PLC.

Global medical technology company BD (Becton Dickinson and Company) needed to assess the torque required to twist off the cap of a drug delivery device as a manufacturing quality control measure. The company were using a manually operated torque tester, but experienced a large variation in results due to differing testing techniques between operators and switched to a Mecmesin Vortex-i PC-controlled torque tester. Stephen Byrne from BD said

“The Vortex-i system has enabled us to eliminate the variability of results experienced with our previous manually-operated testing systems, allowing accurate and consistent testing of the conformance of our drug delivery systems to our stringent in-house standards.”

Mr Keith Borowsky, an eminent orthopaedic surgeon at the University of Brighton Medical School has developed a new orthopaedic prosthesis for shoulder reconstruction. The prostheses is tested with a Mecmesin console-controlled force tester to ensure that they attach correctly to the surrounding bones and tendons, reliably replicating the anatomical structure of a shoulder. This research will ensure that patients retain a good degree of strength and mobility in their replacement shoulder joints. Mr Borowsky said “I am very pleased with both the service from Mecmesin and the MultiTest test system and would recommend it for testing many of the aspects of soft tissue repair in orthopaedics. The MultiTest is easy-to-use and ideal for this application, of testing the fixation of bones and tendons around a prosthesis inserted for fracture of the shoulder.”

Mecmesin will be demonstrating its range of force and torque measurement equipment including the Helixa precision torque tester on stand 602 at Medtec Ireland 2015. Whether you need to know the precise force to actuate a syringe plunger, insert and extract a hypodermic needle, remove an inhaler’s cap, calibrate an infusion pump, or peel open sterile medical packaging Mecmesin has the solution for you. Meet us there and discover how to perform compression, tensile and torque tests on your components, materials and products to maintain quality throughout the design and manufacturing process.

Mecmesin will be demonstrating its range of force and torque measurement equipment including the Helixa precision torque tester on stand 602 at Medtec Ireland 2015. Whether you need to know the precise force to actuate a syringe plunger, insert and extract a hypodermic needle, remove an inhaler’s cap, calibrate an infusion pump, or peel open sterile medical packaging Mecmesin has the solution for you. Meet us there and discover how to perform compression, tensile and torque tests on your components, materials and products to maintain quality throughout the design and manufacturing process.

For more information on these and other medical device test solutions, visit http://www.mecmesin.com/medical-and-veterinary