Early identification of earth faults within mission critical AC or DC control and auxiliary supplies can increase profitability by reducing unscheduled shutdowns and the downtime of valuable assets.

Bender’s insulation monitoring technology combined with earth fault location systems are widely employed on critical control circuit applications to ensure continuity of system operations across sectors including chemical processing, oil & gas, power, and high value production facilities.

Insulation monitoring also provides a real-time value of the insulation resistance level and is a vital continuous check on the health of electrical systems.

BS7671 wiring regulations (clause 557.3.4.1 Note 2) recommend using an unearthed supply for auxiliary circuits where high reliability is required. This is because an unearthed (or IT) system, unlike a TN system is tolerant to first earth faults and will not cut power, which makes it more reliable and safer for mission critical systems, protecting both production and people.

However, the full benefit of an IT system can be realised only by using insulation monitoring devices (IMD), which provide advanced warning of degrading insulation resistances, combined with earth fault detection (EDS) devices which can precisely locate the fault on the system.

Earth Faults are difficult to detect and threat-evaluate due of the nature of circuit design and dependencies. They can cause incorrect switching, false indication, and increase the risk of electric shock, shut-down and fires.

BS7671 clause 411.6.3.1 states “Where an IT system is used for reasons of continuity of supply, an insulation monitoring device shall be provided…”

Insulation monitoring must comply with BS EN 61577-8 which prohibits the use of a widely deployed passive/voltmeter methodology which cannot detect symmetrical faults.

BS7671 clause 557.3.4.3 states: “Except in the case of a SELV or PELV circuit, if an auxiliary circuit is operated unearthed via a transformer, an insulation monitoring device (IMD) according to BS EN 61557-8 shall be installed on the secondary side…”.

Whether an IMD complies with BS EN 61577-8 is determined by the type of system being monitored. Most modern control systems include mixed AC/DC voltages in the distribution network and that means it is important for the insulation monitoring devices to cover mixed signal circuits. Typically, any system with PLC or electronic equipment will be classed as an AC and DC mixed system.

Security of supply is the main priority, but control circuits are also susceptible to malfunctions due to insulation faults. For example, a double symmetrical insulation resistive fault which may not be detected by a circuit protective device, can still cause a false state change on the input of a PLC. This can lead to devastating effects for certain applications, such as incorrect operation of a HV circuit breaker.

BS7671 clause 557.3.201 states: “A control circuit shall be designed, arranged and protected to limit dangers resulting from a fault between the control circuit and other conductive parts liable to cause malfunction (e.g. inadvertent operation) of the controlled equipment.”

Control wiring such as DI/DO rigs are driven by the main auxiliary supply, so if the correct contacts are used, signal cables can also be continuously monitored by Bender devices.

Insulation monitoring technology combined with earth fault location systems developed by Bender are employed in a wide range of critical control circuit applications within industry sectors that simply cannot afford unscheduled shutdowns or interruptions in production and process operations. Examples include battery/charger supplies to tripping circuits in substations, supplies to control circuits in process industry, and other control circuit applications.

Application of the technology and its benefits can be extended to other main circuit distribution systems, where security of supply and advanced warning of developing faults is of paramount importance.

Bender technology can be permanently retrofitted and is also successfully used to locate long standing earth faults via portable terminals.

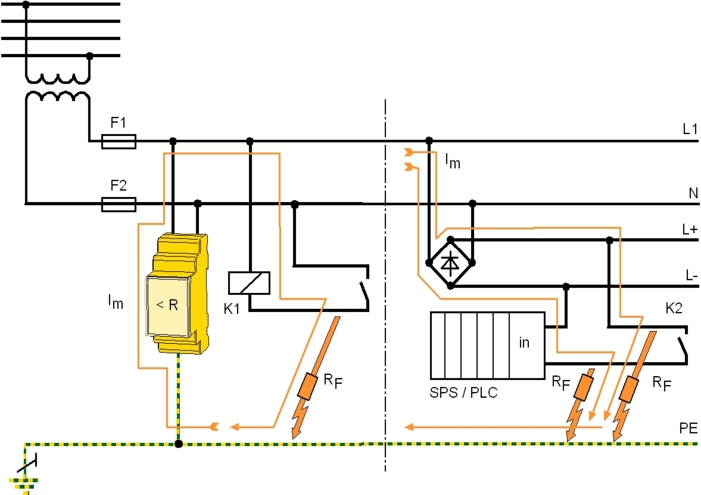

This diagram shows a typical structure of insulation monitoring devices in a control system with fixed and portable earth fault location to precisely identify faults to cabinet/PLC level.

This diagram shows a typical structure of insulation monitoring devices in a control system with fixed and portable earth fault location to precisely identify faults to cabinet/PLC level.