Choosing the pump type that best satisfies a fluid handling application is not necessarily straightforward as there are many factors that influence pump performance. Not least of these is the type of fluid that is being pumped according to AxFlow MD Tony Peters

Choosing the pump type that best satisfies a fluid handling application is not necessarily straightforward as there are many factors that influence pump performance. Not least of these is the type of fluid that is being pumped according to AxFlow MD Tony Peters

Whilst there are any number of applications that will demand a specific pump type, there will be just as many if not more where a relatively simple low maintenance pump type will suffice.

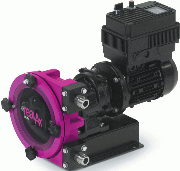

The peristaltic, or hose, pump slots neatly into this category. Suitable for applications where the pumped media can be viscous, of low lubricity or contain solids, the peristaltic pump delivers leak-free operation and high levels of dosing accuracy.

The peristaltic pump is a positive displacement pump where the fluid is held within a hose or tube contained within a casing. The fluid in the hose or tube is moved into and out of the tube/hose by the action of rotating rollers or shoes which alternatively compress and relax the tube/hose. This action forms a vacuum behind the roller or shoe drawing fluid into the hose while the next roller or shoe gently pushes the fluid forward though the hose.

Because the fluid is always contained within the tube/hose, it never comes into contact with the pump’s moving parts. This has the additional benefit of making the pump suitable for hygienic applications as there is no opportunity for leakage of the fluid and subsequent contamination.

Shoes or rollers

Selecting a shoe or roller peristaltic pump is largely dependent on the application and the operating pressures required.

Then there is the power consumption issue to be considered. Roller technology is far more suited to lower pressure applications, typically up to 4bar, and is usually limited to a maximum of 8bar. Therefore with roller peristaltic pumps smaller drives are required which results in less power being consumed. Shoe compression pumps are more suited for applications demanding operating pressures up to 16bar and higher flowrates, making it the obvious choice for medium and higher pressure applications. This pump is very much a robust, workhorse and built for the most arduous of operating conditions and fluids.

Generally, the inspection window of a peristaltic pump enables the operator to check the oil lubricant level in the pump housing. The design of the inspection window in AxFlow’s realAx peristaltic pump, also incorporated in its range of shoe compression hose pumps, said to make it easy for the operator to access the rotor and the hub and easy to change the number of shims in order to accommodate pressure changes demanded by the application. This facility eliminates the need to remove the front cover of the pump case, thereby saving time and making maintenance easier.

Whether the application involves dosing small, precise quantities of fluid at low pressures or high accuracy pumping of large volumes of viscous or abrasive products, peristaltic and hose pumps could be the best solution.

Axflow

T: +44 (0)20 8579 2111