A new wireless solution from thermal imaging expert Flir is proving to be crucial to the predictive maintenance programme for Medite Europe, which produces medium density fibreboard (MDF), a construction material, at its production plant in Clonmel

A new wireless solution from thermal imaging expert Flir is proving to be crucial to the predictive maintenance programme for Medite Europe, which produces medium density fibreboard (MDF), a construction material, at its production plant in Clonmel

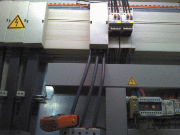

The Medite product range includes seven families of MDF products and many variants, with over 400 possible specifications. All are manufactured at the Clonmel factory where the company strives for high productivity. A key element of this is ensuring that any electrical or mechanical fault is spotted and repaired before it becomes a production-disrupting failure. The detection task is where the company makes use of infrared measuring technology.

Adding connectivity to infrared

The regular infrared maintenance surveys conducted have helped to ensure the factory’s smooth running for more than 10 years. Recently, however, the company has been able to add greater value to thermographic inspections at Medite Europe thanks to a new introduction by Flir, the thermal imaging specialist. This is a Bluetooth wireless solution between the infrared camera and a measuring instrument called Meterlink. It allows measurement data from meters to be embedded in an infrared image. In other words, it brings greater accuracy and intelligence to the infrared inspection. The correlation between temperature and electrical load is well established and for years thermographers have included load ratings where relevant. Thermographic consultant, Bob Berry explains: “The most common way of doing this is to take readings using a clamp meter, write them down and add them to the report later.”

Berry, of Thermal Vision, is a certified Level 3 thermographer and he performs more than 100 inspections per year. This creates a lot of data and it is all too easy for readings from different instruments to be lost or mixed up. “The more time it takes me to assimilate the information, the longer the report generation process becomes, and that means I have less time to spend in the field which is where I need to be,” he says.

Instruments talk to camera

Instruments talk to camera

The new Flir Meterlink facility is available on a variety of Flir infrared cameras including the Flir T425 mid-range model which used at this inspection. It is suitable for a wide range of electro-mechanical inspection tasks that are common at larger industrial plants such as Medite Europe.

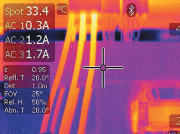

Berry says: “The menu system of the Flir T425 camera is intuitive and easy to use and it has many analysis tools that can be set up accordingly. Its Meterlink feature allows the camera to receive data automatically from an Extech EX845 clamp meter and this is a function that is easier to use than I expected. Its effectiveness is obvious, both in the field inspection and at the post report processing stage.”

Easy to use

Berry says the straightforwardness of Meterlink means he is much more likely to take time to stop and use the clamp meter than when he is taking independent readings and making notes. He explains: “The clamp meter is simply fitted to the first phase and the infrared image frozen complete with embedded current reading. The camera then prompts you to add more current readings, one at a time, each stored in the appropriate image.”

On this basis three phases require three readings. No notes need to be taken and there’s no danger of the readings being attributed to the wrong job or lost. It may require slight changes to the inspection routine but this is not inconvenient and makes you focus on what you are doing.”

No mix-up

No mix-up

The saved measurements are fully accessible in the Flir analysis and reporting software Reporter 8.5 and easily added in the results tables. This means, for the first time, thermographers can be certain the current readings tally fully with the thermal image. It eliminates all possibility of any mix-up. Additionally the title and location of individual faults can be saved directly in the image as voice or text comments and annotations.

“This combination of a Flir infrared camera and Extech clamp meter rules out the possibility of confusing the location, the equipment or load data from individual faults,” Berry concludes: “With more work being done in the field it also reduces associated office time and frees me up to spend more time onsite with customers.”